Latest Industry News

Welcome to JB Packing's blog section. As a leading tin box manufacturer and supplier based in Dongguan, China, we share insights, updates, and industry trends related to tin packaging. Explore our blogs to stay informed about our latest innovations, product highlights, and expert tips on tin packaging solutions. Stay connected with JB Packing for all things related to quality tin packaging.

Beyond Plastic: 2026 Sustainable Packaging Regulations & The Tinplate Solution

The era of "cheap plastic" is over. With the 2026 implementation of strict Extended Producer Responsibility (EPR) laws, the bill is coming due. Here is why Tinplate is your safest route to compliance.

2026 Color Trends for Custom Tins: Translating Pantone to Metal

A Pantone color looks one way on a screen, but completely different on steel. In this guide for designers, we explore how to accurately translate the 2026 color palette onto metal packaging using White Bases and Transparent Inks.

2026 Tea & Coffee Packaging Trends: Why "Airtight" is the New Standard

For premium tea and coffee brands, 2026 is the year of "The Seal." Consumers are demanding better freshness protection and zero-waste solutions. We analyze why major brands are ditching composite pouches for airtight tinplate packaging.

Beyond Glossy & Matte: The Ultimate Guide to Tin Box Varnishes & Finishes In 2026

Your last guide covered the costs; this guide covers the "Wow" factor. From the 3D visual trickery of Spot UV to the vintage texture of Crackle Varnish and the premium safety of Internal Gold, learn how to make your packaging unforgettable inside and out.

Tinplate vs. Aluminum: Which Metal is Right for Your Packaging?

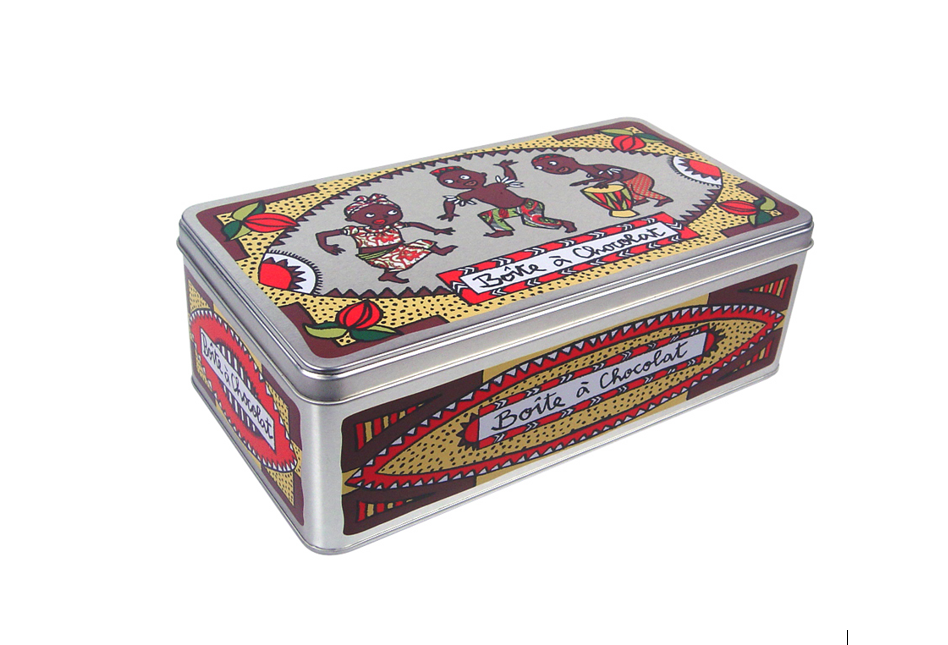

Custom printed rectangular tinplate box for chocolates featuring vibrant African tribal art design, showcasing the rigid structure of steel packaging compared to soft aluminum.

From PDF to Product: The Ultimate Guide to Tin Box Prototyping & Sampling

The scariest part of custom packaging is wondering if the final product will match your vision. In this guide, we break down the 4 levels of prototyping—from digital 3D renders to full metal samples—ensuring your "PDF" looks exactly like the "Product" on the shelf.

Vetting Your Supplier: The Ultimate Checklist for Auditing a Tin Box Manufacturer

Not all tin box manufacturers are created equal. Whether you are a global brand or a fast-growing startup, auditing your supplier is critical for long-term success. We provide a comprehensive checklist covering certifications, production transparency, and quality control to help you choose the right partner.

The Power of "Limited Edition": How Seasonal Tin Packaging Drives Impulse Buys

Why do consumers gravitate towards seasonal products? It’s the psychology of scarcity. We explore how "Limited Edition" tin packaging can transform your product into a collectible item, boosting brand loyalty and driving impulse buys for holidays in 2026.

Is Your Product Secure? 3 Innovative Ways Metal Packaging Prevents Tampering

Brand protection starts at the lid. From high-end supplements to luxury spirits, product integrity is non-negotiable. We break down the three most effective ways to make your metal packaging tamper-evident and secure against counterfeiting.

Scaling Small: How Emerging Brands Can Master Custom Tin Packaging Without High MOQs

Growing a brand is hard, and packaging costs shouldn't be the barrier. In this guide, we reveal how startups can achieve a "Big Brand" look with custom tins by leveraging existing molds, optimizing order quantities, and choosing the right printing methods to keep MOQs manageable.

2026 Forecast: 4 Tin Packaging Trends That Actually Matter

Looking ahead to 2026, metal packaging is evolving. We analyze the four key trends driving the industry: the rise of pocket-sized FMCG tins, the shift toward "Quiet Luxury" textures, the demand for "Fortress" level freshness, and the strategic move to existing mold sourcing. Stay ahead of the curve with JB Packing’s 2026 forecast.

The Zero-Waste Revolution: Premium Tin Packaging for Candles & Bath Gift Sets

Why are luxury beauty brands switching from plastic to metal? From seamless candle tins that never leak to premium bath gift sets that customers keep forever. Discover how JB Packing helps you create the ultimate "unboxing experience" for self-care products.

Winning the Shelf: Premium Tin Packaging for Biscuits, Cookies & Chocolates

Biscuits breaking during shipment? Grease stains on the packaging? We solve the two biggest headaches for confectionery brands. Discover how JB Packing's "One-Stop" insert solutions and oil-resistant coatings ensure your cookies arrive perfect. Plus, why automated tin production can actually be cheaper than premium paper boxes.

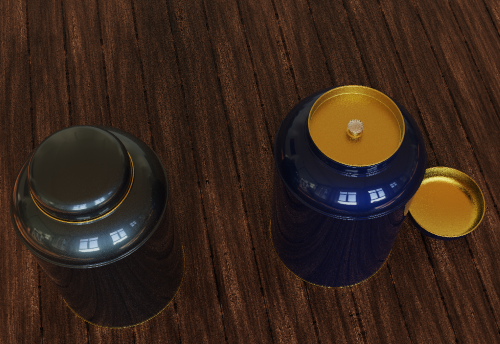

Premium Preservation: The Guide to Air-Tight Tin Packaging for Tea & Coffee

Freshness is the currency of the tea and coffee industry. We explore the science behind air-tight tin packaging, comparing standard plug-in lids vs. high-end welded screw-lid structures. Learn how to block oxygen, light, and moisture to preserve delicate aromas.

Seasonal Packaging Success: Planning Timelines for Christmas & Holiday Tins

Missed the Q4 holiday deadline? Never again. We break down the "Reverse Timeline" for Christmas packaging, proving why April/May is the critical ordering window. Plus, discover how using our existing molds saves you $5,000 and 40 days of lead time.

Optimizing Tin Box Logistics: Sustainable Shipping, Recycling, and ESG Compliance

Shipping air is expensive. We analyze how to optimize tin box logistics through nesting and master carton efficiency. Plus, a deep dive into tinplate's 100% recyclability, soy-based inks, and how our SMETA 4-Pillar audited packaging helps you meet ESG goals.

Structural Innovation: The Guide to Custom Hinges, Compartments, and Complex Tin Tooling

Looking for complex tin packaging? We detail the structural challenges of custom hinges, multi-product compartments, and double-layered tins. Learn the true cost difference between standard and custom tooling, and the long-term ROI of mold ownership.

The Ultimate Guide to Tin Box Printing and Decoration: Embossing, Finishing, and Cost Analysis

Stop guessing the cost of premium tin finishes. This technical guide explores the difference between CMYK and Pantone, details the "Borrowing the Base" metallic process, and reveals the high cost and risks associated with Soft-Touch varnish and custom embossing lead times.

Food-Grade Tin Packaging: Safety Standards, Coatings, and Why Tins Beat Other Materials

Is your food packaging safe? This comprehensive guide details the mandatory safety standards (HACCP, FDA/EU), explains essential custom internal coatings (matched by food acidity), and analyzes why infinitely recyclable tinplate offers superior barrier protection and sustainability compared to plastic and cardboard.

FAQs for Tin Box Buyers: Answering Your Top 10 Questions on MOQ, Pricing, and Lead Time

Sourcing custom tin boxes? Get straight to the critical business answers. We break down the top 10 questions buyers ask, including precise MOQs (starting from 3,000 pcs), tooling costs (USD $2,500–$5,000), exact lead times, and food safety standards (HACCP/Food Grade compliance).