Beyond the Rectangle: How Our Dongguan Engineers Bring Complex 3D Tin Box Designs to Life

1. Introduction: The Need for Packaging That Stands Out

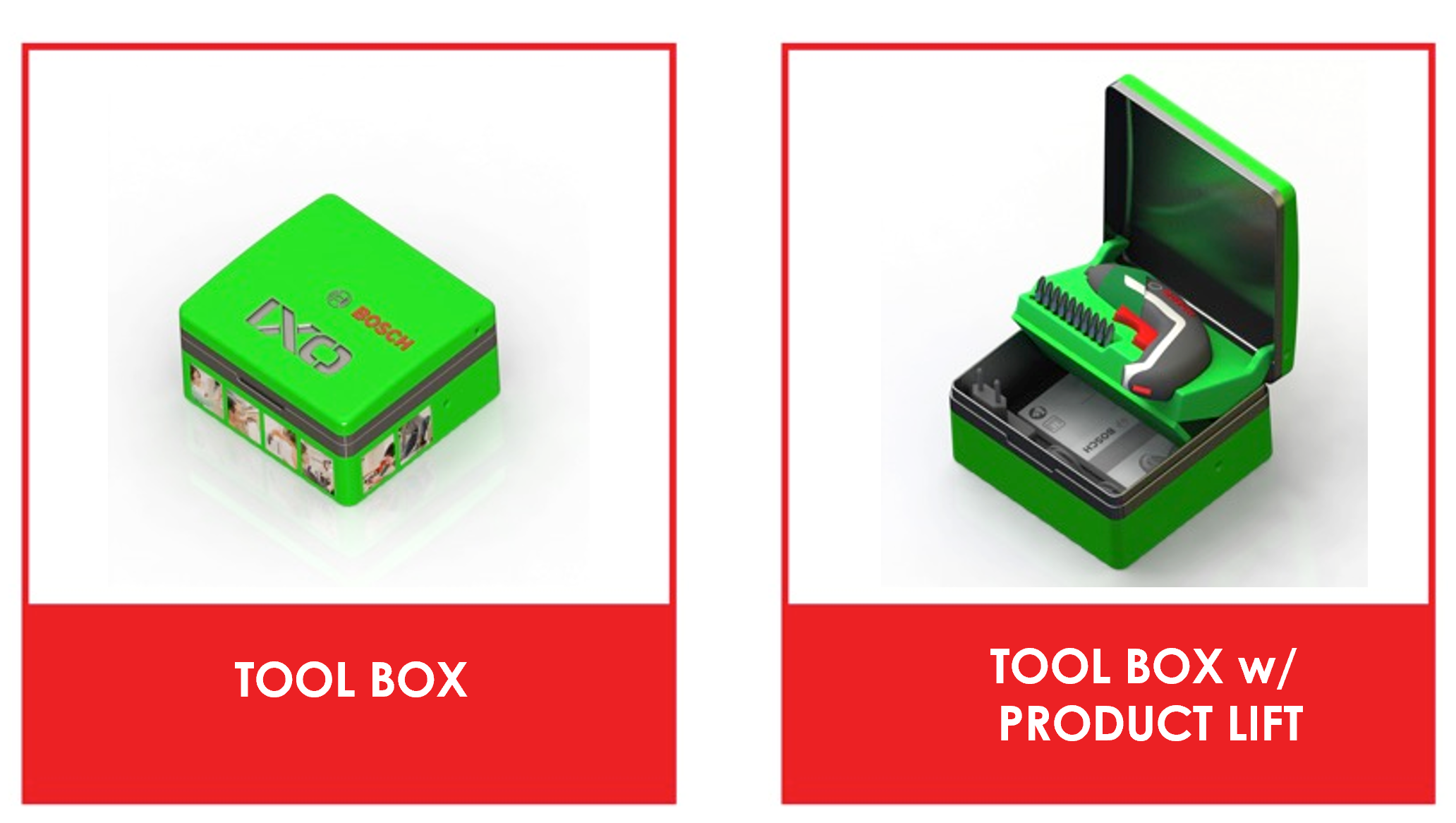

In the crowded retail world, a standard rectangular tin box is no longer enough to capture consumer attention. Today, leading brands are demanding unique, three-dimensional packaging that serves as a collectible or a powerful marketing statement.

The challenge for procurement managers is finding a manufacturer who can reliably translate complex industrial designs—like a custom car shape, a two-tiered holiday village, or a spherical ball tin—from concept art into millions of units with perfect consistency.

At JB Packing Industrial Co., Ltd in Dongguan, our success isn't just in running our ISO-certified production lines; it's in the engineering mastery required to produce complex 3D tin structures. Here is how our specialized capabilities in Dongguan ensure your most ambitious tin packaging ideas become a reality.

2. From Concept to CAD: The Rapid Prototyping Advantage

Bringing a complex shape to life requires more than just a sketch; it demands precision engineering from the start.

Engineering-First Assessment: We start every complex project by conducting a deep-dive analysis of your design. Our engineers use advanced CAD (Computer-Aided Design) software to identify potential manufacturing pinch- points related to metal stress, mold lines, and assembly before a single piece of tinplate is stamped.

Rapid Sample Prototyping: Instead of waiting months for a physical prototype, our integrated R&D facility allows us to quickly develop 3D-printed molds or rapid mock-ups. This enables your brand team to hold and approve the final physical dimensions and structure faster, significantly shortening the development cycle.

The Dongguan Difference: Our location in the heart of the world’s manufacturing hub means we have unparalleled access to specialized tooling suppliers and advanced material testing, ensuring our custom molds are built for longevity and high-volume production.

3. The Art of the Mold: Precision Tooling for Complex Shapes

The quality of a complex tin box is 90% dependent on the mold (tooling). Poorly made molds result in misaligned seams, weak hinges, and high defect rates—especially for intricate 3D shapes.

Dedicated Tooling Facility: Unlike suppliers who outsource, we operate our own in-house mold and tooling shop. This gives us direct, real-time control over the tolerances and material quality of every single mold created.

Mitigating Flaw Risks: Complex shapes often involve deep drawing or multiple punching steps. Our tooling engineers specialize in designing molds that manage these stresses, eliminating common flaws like wrinkling, cracking, and surface distortion, guaranteeing structural integrity for forms beyond the simple cube.

Lifetime Maintenance: For large-volume clients, we treat the tooling as a long-term asset. We guarantee meticulous maintenance and refurbishment of your custom mold, ensuring that the first 10,000 units are structurally identical to the five-millionth unit.

4. Advanced Finishing: Making Your Design Shine

Once the 3D shape is perfected, the visual details must elevate the design. Our advanced printing and finishing techniques ensure your graphics and brand logos are executed flawlessly on curved or complex surfaces.

Embossing and Debossing Mastery: For adding tactile, premium details, our presses can apply sharp, high-relief embossing or debossing to contoured surfaces, ensuring your logo stands out clearly, even on spherical or conical designs.

Specialized Printing: We offer advanced printing services, including Spot UV, Metallic Inks, and Matt/Gloss Varnish Combinations, allowing you to create stunning contrasts and textures that highlight the unique geometry of your custom tin.

Flawless Alignment: Printing on an unusual shape is a technical challenge. Our highly precise automated lines ensure the graphic alignment is perfect across all panels, seams, and hinges, maintaining brand consistency across the entire production run.

5. Security of Supply for Complex Orders

Choosing a complex tin design should not mean sacrificing reliability or volume.

By combining an integrated tooling shop with a 5-million-unit monthly capacity—all operating under strict ISO9001 quality management—we offer B2B buyers the assurance that their unique, high-value packaging will be delivered on time and to specification, season after season.

Conclusion: Partner with Engineering Excellence

Your packaging is a physical extension of your brand story. Don't compromise your bold design vision with a manufacturer whose capabilities end at the standard square.

Partner with JB Packing Industrial Co., Ltd in Dongguan to leverage the engineering expertise, precision tooling, and high-volume capacity required to transform your most complex 3D tin packaging concepts into market-ready realities.

Ready to Challenge Our Engineers? Pleaes contact us at any time!